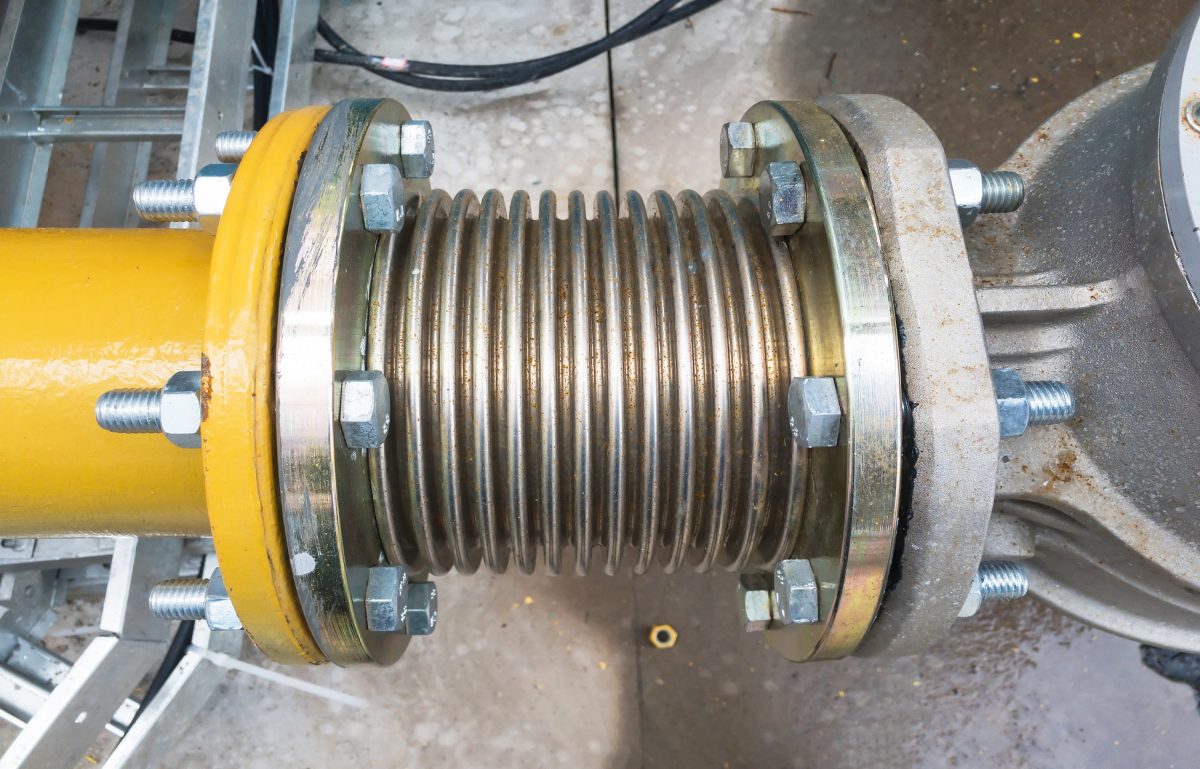

Expansion joints play an essential role in various industrial settings. These flexible components are designed to accommodate movement, vibration, and thermal expansion within systems like pipelines, ductwork, and machinery. Without them, many industrial processes would face frequent disruptions or costly damage. Below, we’ll explore some of the primary industrial environments that rely on expansion joints and why they are so critical.

Power Generation Plants

Power generation plants heavily depend on expansion joints to maintain efficient operations. High temperatures generated during energy production cause pipelines and ductwork to expand and contract. Expansion joints mitigate the stress caused by this constant movement, preventing cracks or leaks. They also improve the durability of critical systems, reducing the overall need for repairs. Power plants that integrate expansion joints can keep their systems running smoothly under intense thermal pressures.

Chemical Processing Plants

Chemical processing plants handle some of the most extreme and challenging conditions in the industrial world. These facilities work with highly corrosive materials, strong chemicals, and extreme temperatures. Expansion joints made of specialized materials, like PTFE or stainless steel, are specifically designed to withstand these harsh environments. Their flexibility allows them to absorb thermal expansion while also protecting systems against chemical wear. Using expansion joints helps maintain safety and efficiency, especially when working with volatile substances or high-energy reactions.

Oil and Gas Refineries

The oil and gas industry frequently operates under high-temperature and high-pressure conditions, particularly in pipelines, storage systems, and processing units. Expansion joints help these systems adapt to shifts caused by intense heat or pressure without compromising structural integrity. Refineries rely on them to safely handle volatile fluids and gases while ensuring processing facilities operate without unexpected shutdowns. Their design minimizes the risks posed by wear, helping refineries meet rigorous safety and reliability standards.

HVAC Systems

Large-scale heating, ventilation, and air conditioning (HVAC) systems are another common destination for expansion joints. These systems experience frequent movement and vibration due to changes in temperature and airflow. Expansion joints absorb these movements and minimize vibration, which prolongs equipment life while maintaining steady performance. Facilities like office towers, shopping malls, and hospitals all benefit from the seamless operation of their HVAC systems, thanks in part to expansion joints.

Wastewater Treatment Plants

Wastewater treatment plants are another example of industrial environments that use expansion joints effectively. These facilities deal with fluctuations in flow rates, temperature changes, and corrosive waste materials, so it makes sense that they would benefit from the use of expansion joints. Expansion joints installed in pipelines and processing systems allow for flexibility during these changes and protect against long-term damage caused by environmental factors. By absorbing stress and movement, they help wastewater plants treat water efficiently without costly interruptions or repairs.

Why Expansion Joints Matter

Expansion joints are indispensable to industrial environments that function in harsh or demanding conditions. Whether they’re handling the extreme heat of power plants, resisting corrosion in chemical processing plants, or adapting to vibrations in HVAC systems, these components keep critical systems operational.